For over 15 years, thanks to our oxidation activator, those businesses and customers who have placed their trust in our products, have been able to forget about the problem of uncontrollable and slow oxidation (it can take up to several months depending on the environmental conditions).

At LINEACOR® we have a long history of developing products for the treatment of Cor-Ten® steel, but if one product is worth highlighting, then it is act-COR. Our act-COR oxidation activator is undoubtedly our most important product and also the one that is appreciated the most by all of our customers. But less well known – and this is what we want to focus on here today – is the Gel version. This is called act-COR Gel, a version of the original product that was developed based on feedback from many of our customers, who were looking for greater control when applying act-COR, especially onto surfaces that were difficult to access. Listening to our customers resulted in act-COR Gel being developed.

With act-COR Gel a more durable oxidation is achieved when used in demanding working conditions

Both of our act-COR products deliver exceptional, high quality results, as well as being highly efficient, which in turn provides greater benefits to the businesses that use these products for their projects. At the same time, each product does have different characteristics, which means that each one of them will deliver considerably different results, offering not only activation of the oxidation, but also greater possibilities when it comes to achieving a more personalized finish, allowing each client to obtain the results they want.

The main advantage of using our oxidation activator in either liquid or gel format, is not only the superior creative possibilities, but also the fact that applying the product onto practically any type of surface is greatly improved for any type of Cor-Ten® steel structure. Horizontal surfaces that are easy to treat, as well as irregularly shaped or difficult to access surfaces, vertical surfaces, ceilings, spherical, tubular surfaces, etc. are all suitable for treatment with the act-COR range.

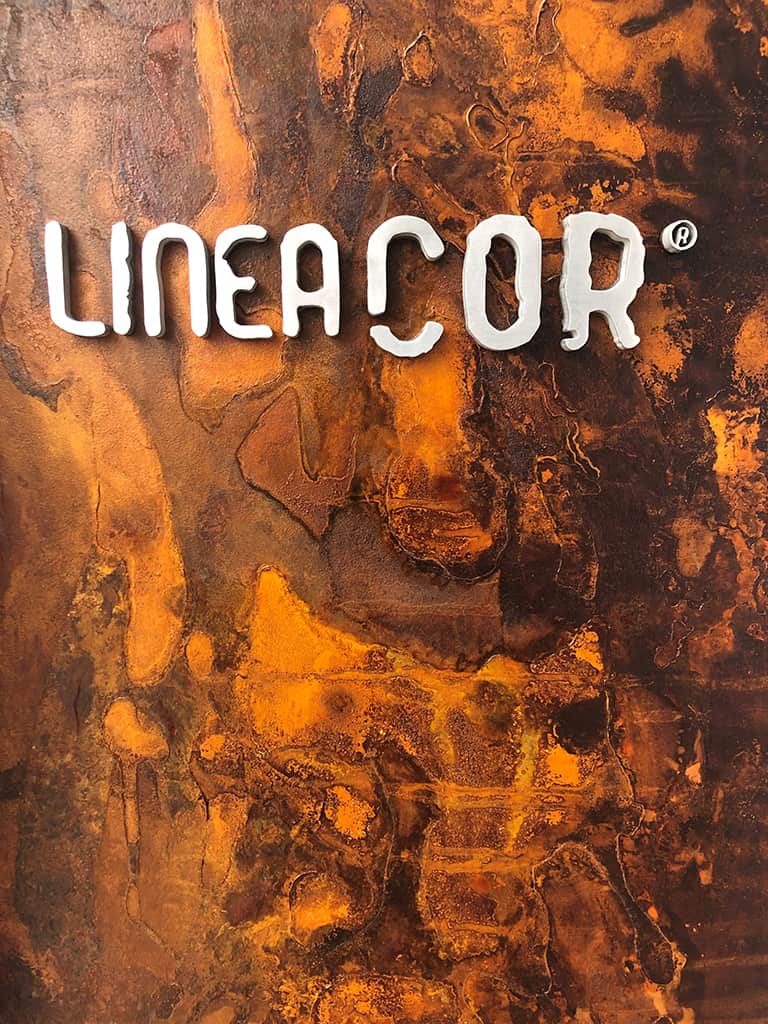

With act-COR Gel, a more durable oxidation is achieved when used in demanding working conditions, while the resulting oxidation is both lighter and more orange, which are the key primary colours in an oxidation. In addition, the finish produces less rust drag (i.e. less powder residue resulting from the oxidation) once the application is completed. The latter favours the use of bp-COR and improves its adherence onto the steel. The “stability” of the achieved finish (i.e. the aesthetic appearance) is also extended, lasting for a longer time.

Thanks to the simultaneous use of act-COR Gel and act-COR liquid, there have been projects where unique results were achieved, with an artistic character that delivers totally unique and customizable results. The use of act-COR Gel gives more textured tones, but using a combination of both products broadens the chromatic range of the oxidation even more.

Do not forget that you can always (if so desired) use the original liquid act-COR, which will give the oxidation a uniform, more regular appearance. You can also achieve darker, more “aged” oxidation tones that reflect the passage of time. All of this can be achieved within a few days and backed with the guarantee and experience our customers associate with LINEACOR products.

We are always at your disposal to clarify any doubts, questions or suggestions you may have. Tell us about your project and your needs and we will do our best to help and advise you how to make your oxidized Cor-Ten® steel project a huge success, and delivered at an unbeatable cost-benefit ratio.

-

act-COR Oxidation activator GEL22,00€ – 850,00€

-

act-COR Rust activator17,00€ – 676,00€